What Is Vehicle Acoustics Management?

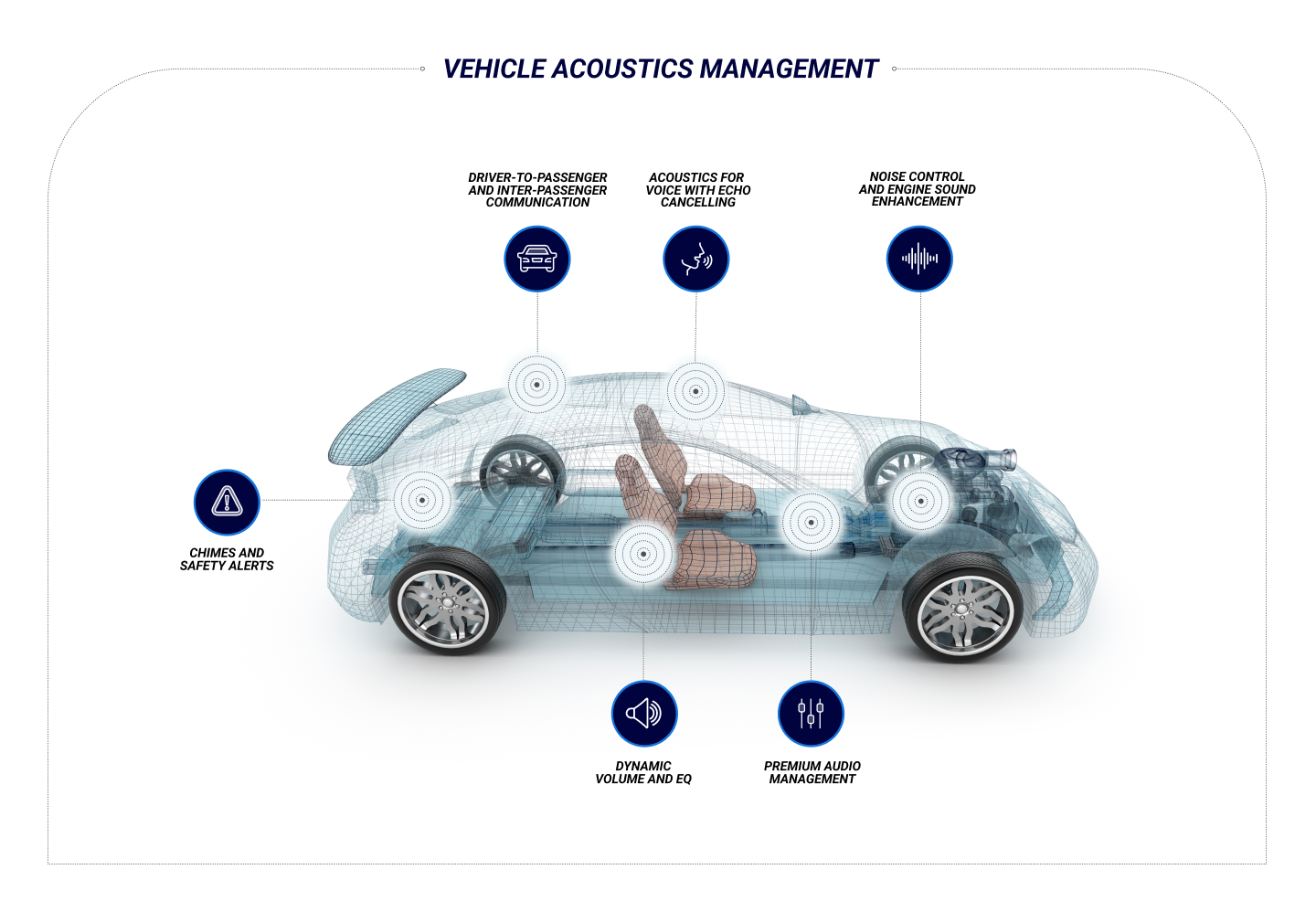

Vehicle acoustics management aims to refine noise and vibration and eliminate or minimize unpleasant sound characteristics in cars. Enhanced vehicle acoustic systems impact a vehicle’s dynamic performance, luxury appeal, and responsiveness.

Car acoustics comprise expected or wanted sounds, such as the closing sound of the glovebox, or unwanted sounds, such as squeaks and rattles, which indicate poor car quality. Most automakers are looking at ways to reduce unwanted vehicle sounds through refined vehicle acoustics systems, integrations, and sound quality engineering for competitive market advantage.

For efficient vehicle noise management, there are several advanced materials and hardware that enable sound insulation, absorption, and robust sealing. Several automotive software solutions aim to deliver superior sound quality and optimized vehicle configuration. Some of these software tools also bring noise and vibration data to life through simulations that simplify decision-making and help build N&V designs with confidence.

Goals of Vehicle Acoustics Management

- An engine that is idling smoothly

- A quiet riding experience under light engine loads

- Linear acceleration under high engine loads

- Facilitate a sound character and acoustic targets appropriate for that class of vehicles

What Are Vehicle Acoustics?

Vehicle acoustics refers to the overall in-car sonic experience. It relates to the production, control, effect, and reception of sound by drivers and passengers in a vehicle. The two primary performance indexes used to measure the quality of vehicle acoustics are noise and vibration.

Noise and vibration in an automobile are an outcome of the synthesis of sound at the system, subsystem, and component levels—including those of the engine, tires, pumps, and exhaust systems.

Automakers and OEMs focus on refining vehicle noise and vibration performance, which are also ride quality and reliability measures. The rising adoption of vehicle electrification, lightweighting, and software-defined vehicles are also paving the way for better noise and vibration (N&V) development. Significantly, optimized automobile acoustics improve customer experiences.

Sources of Vehicle Noise

Moving and stationary vehicles create hundreds of different noises. An automobile has two primary sources of noise: interior and exterior.

| Exterior Noise | Interior Noise |

|---|---|

| Exterior noise generates from external sources related to a vehicle. | Exterior noise is generated by the engine, tires, exhaust system, or individual exterior sources such as a pass-by vehicle. |

| Interior noise is generated from a whole vehicle or single components within the car, including vibrations such as the dash panels and floor. | Specific benchmarks tested for interior noise are resonance noise, brake noise, and audio acoustics for communication and alerts. |

Most noises experienced in a vehicle are either air-borne or structure-borne, which follow two different categories of transmission paths.

Air-borne noise: These emerge from outside the vehicle compartment. Direct air-borne noise paths are a passageway created when there is a lack of sealing between a vehicle’s interior and exterior environments, such as the door panels. The acoustic sources for air-borne noises include valves and electric generators.

Structure-borne noise: This is the outcome of vibrations from outside the vehicle causing the panels surrounding the internal cabin to vibrate and make noise. For example, the vehicle suspension system is present in the structure-born transmission path. Structure-borne noise usually dominates at lower frequencies.

In terms of the physical nature of noise, it can emerge from multiple sources in an engine. The engine is a primary source of noise in a vehicle.

The Three Types of Engine Noises

1. Mechanical Noise: Mechanical noise is due to the inertia effect of moving parts under air pressure or inertia force; it can be called impact-induced or vibration-radiated. Mechanical noise results from bearings defects, bent shafts, or shaft misalignment.

2. Combustion Noise: Any sound caused by cylinder pressure is known as combustion noise. Combustion noise emanates through engine blocks and parts.

3. Aerodynamic Noise: Aerodynamic noise stems from the car engine cooling fan or the airstream created by vehicle movement and is a dominant noise inside the car.

In addition to these primary noise sources, there are many secondary noise sources such as brakes and electrical and mechanical accessories. In addition, noises such as squeaks and rattles generated by the dynamic displacement are indirect sources of noise in a vehicle.

At the developmental and R&D stages, auto developers must consider two broad strategic measures when addressing vehicle noise.

Benchmark Study: A benchmark study helps determine how a user’s experience and expectations from a product have changed over time. Analyzing their systems also helps determine what competitors are doing in the same space.

Target Setting: Target settings help establish performance goals and design requirements and assess factors such as government regulations.

Determining the optimum quality of automobile acoustics is a complex process deeply rooted in physics and mechanics. As a result, the solution cannot be an analytical method alone. Instead, several statistical approaches exist to accurately study and understand vehicle noise, such as the finite element and boundary element method and the modal synthesis and analysis method.

These studies help determine and control the entire chain of noise generation and propagation mechanism in an automobile for the best outcome. For instance, when a car is in motion at a low speed, the engine’s sound must be carefully balanced to avoid jarring noises. On the other hand, if the vehicle is moving at high speed, it is crucial to maintain low wind noise levels for high acoustics quality.

The noise and vibration experienced in a vehicle depend not only on the noise sources but also on other factors such as the structure and design of the automobile and subjective tastes. For example, most parts of a vehicle, including the engine and suspension, are connected to the vehicle’s body and directly impact the sound power. Similarly, structures such as car doors should be designed to reduce local vibrations.

It is impossible to standardize a single set of noise and vibration targets for vehicles as every vehicle has unique noises. Government regulations to minimize risks and control noise emissions will also factor in.

Check Out Our Other Ultimate Guides